What are the dimensions of a large pizza box? Understanding these measurements is crucial for pizza packaging, delivery, and even environmental impact. Variations exist across brands and sizes, impacting everything from stacking efficiency to material use. This analysis delves into the factors influencing large pizza box dimensions, comparing different brands and sizes, and exploring practical applications and technical specifications.

The standard dimensions of a large pizza box vary significantly depending on the brand. Factors like pizza size, material properties, and the need for protection during transit all influence the final measurements. This article examines these crucial elements and offers a comprehensive overview.

Pizza Box Dimensions – General Overview: What Are The Dimensions Of A Large Pizza Box

Large pizza boxes, crucial for safe and convenient transport, come in a range of dimensions. Understanding these dimensions is important for both pizza businesses and consumers. Accurate sizing ensures that pizzas are properly protected and transported effectively.Typical large pizza box dimensions vary slightly based on the brand and size of the pizza. These differences influence packaging efficiency and consumer experience.

Standard units of measurement are used to define these dimensions, allowing for consistency and easy comparison across various brands.

Typical Large Pizza Box Dimensions

Large pizza boxes generally measure between 12-16 inches in length and width, and 2-3 inches in height. These dimensions are influenced by the need to accommodate the pizza, its toppings, and a suitable margin for protection during transit.

Variations Across Pizza Brands and Sizes

Different pizza brands might utilize slightly different dimensions for their large pizza boxes. Variations can occur due to manufacturing processes, the desired presentation of the pizza, or the type of pizza (e.g., deep-dish vs. thin crust). The size of the pizza itself also impacts the dimensions of the box, with larger pizzas requiring correspondingly larger boxes.

Standard Units of Measurement

Standard units of measurement for pizza box dimensions are inches (in). This allows for precise measurements and comparability across different brands and locations. This standard unit is widely recognized and facilitates communication in the pizza industry.

Factors Influencing Design

Several factors influence the design of large pizza boxes. These factors include the need for adequate protection during delivery, the weight and size of the pizza, the materials used in the box construction, and the desired presentation to the customer. Design considerations also include ease of handling and stacking.

Impact on Pizza Packaging and Delivery

The dimensions of large pizza boxes significantly impact the packaging process and delivery. Properly sized boxes ensure the pizza is well-protected during transport, minimizing the risk of damage. Furthermore, efficient box dimensions allow for easier handling and stacking, optimizing storage and transportation efficiency in restaurants and delivery services.

Comparison of Large Pizza Box Dimensions

| Brand | Length (in) | Width (in) | Height (in) |

|---|---|---|---|

| Domino’s | 14 | 14 | 2 |

| Pizza Hut | 15 | 13 | 2.5 |

| Little Caesars | 13 | 14 | 2.25 |

| Papa John’s | 14.5 | 14.5 | 2.75 |

Note: The dimensions provided in the table are approximate and may vary slightly based on specific pizza sizes and promotions.

Factors Affecting Box Dimensions

Pizza box dimensions are not arbitrary; they are carefully considered to balance various factors. The primary goal is to create a box that safely and securely holds the pizza while maintaining structural integrity during transit. This necessitates a thorough understanding of the factors influencing box design.Pizza box dimensions are intricately linked to the size and shape of the pizza itself.

A larger pizza necessitates a correspondingly larger box to accommodate it without compromising its integrity. Furthermore, the type of pizza (e.g., deep-dish, thin crust) can affect the necessary height and overall dimensions.

Pizza Size and Shape

Pizza size directly dictates the minimum box dimensions required for proper containment. Larger pizzas require larger boxes, increasing the surface area and volume needed to prevent damage during transit. The shape of the pizza, whether round, square, or rectangular, also influences the box design. For instance, a deep-dish pizza necessitates a taller box compared to a thin-crust pizza of the same diameter.

Material Properties

The material used to construct the pizza box significantly impacts its dimensions. Different materials offer varying levels of rigidity, strength, and cost-effectiveness. The choice of material affects the box’s ability to withstand pressure during handling and transport.

- Cardboard: A common material for pizza boxes, cardboard’s strength and cost-effectiveness make it a popular choice. The thickness of the cardboard directly correlates with the box’s ability to support weight and withstand pressure. Thicker cardboard allows for larger and potentially taller boxes, whereas thinner cardboard might necessitate smaller, shorter boxes to prevent collapsing.

- Corrugated cardboard: This material, characterized by its ribbed structure, provides enhanced strength and rigidity compared to standard cardboard. Corrugated cardboard boxes can accommodate heavier pizzas and withstand greater pressure during transit, enabling larger or taller dimensions. Examples include boxes used for large, multi-topping pizzas or pizzas with significant weight due to ingredients.

- Plastic: Plastic pizza boxes, though less common, offer water resistance and a longer lifespan compared to cardboard. Plastic boxes can be molded into specific shapes, potentially influencing dimensions, and have a different resistance to pressure compared to cardboard. However, the cost is often a factor. Examples of plastic boxes are used for pizza take-out, offering a slightly different dimension profile.

Structural Integrity, What are the dimensions of a large pizza box

The structural integrity of the pizza box is paramount to prevent damage to the pizza during transit. The relationship between dimensions and structural integrity is crucial. A box that is too small or poorly constructed will crush under pressure, potentially damaging the pizza. Conversely, an overly large and heavy box may be unnecessarily expensive and unwieldy. This relationship is crucial for cost-effectiveness and efficient shipping and handling.

- Pressure Resistance: The box’s ability to withstand pressure is directly linked to its material, thickness, and design. A strong correlation exists between the box’s dimensions, its construction, and the maximum pressure it can sustain. For example, a thicker, more rigid cardboard box can accommodate larger pizzas and greater transit pressure.

- Weight Capacity: The pizza’s weight, combined with any additional toppings or ingredients, must be considered when determining the box’s dimensions. A box’s dimensions must support the weight of the pizza without collapsing or deforming.

Material Comparison

Different materials used in pizza boxes exhibit variations in their dimensions. The thickness and rigidity of cardboard or corrugated cardboard directly influence the box’s maximum size and weight capacity. Thicker cardboard enables larger boxes, while thinner cardboard necessitates smaller ones. Plastic boxes, due to their molding capabilities and inherent strength, can sometimes have varied dimensions compared to cardboard boxes for the same pizza size.

| Material | Thickness (approx.) | Pressure Resistance | Dimensions (example) |

|---|---|---|---|

| Cardboard | 0.5-1 mm | Moderate | L: 16″, W: 12″, H: 2″ |

| Corrugated Cardboard | 1-2 mm | High | L: 18″, W: 14″, H: 3″ |

| Plastic | Variable | High | L: 17″, W: 13″, H: 2.5″ |

Optimal Dimensions

Optimal pizza box dimensions balance the needs of the pizza’s size and structural integrity. A well-designed box will accommodate the pizza safely and efficiently, without being overly large or cumbersome. This requires careful consideration of material properties, pressure resistance, and the weight of the pizza.

Practical Applications of Dimensions

Pizza box dimensions are not merely a matter of aesthetics; they significantly impact various aspects of the pizza business, from the production line to the customer’s table. Understanding these dimensions is crucial for efficiency, cost-effectiveness, and a positive customer experience. Proper box design facilitates smooth handling, reduces waste, and ensures safe and convenient delivery.The dimensions of a pizza box dictate how easily it can be stacked, transported, and ultimately, enjoyed by the customer.

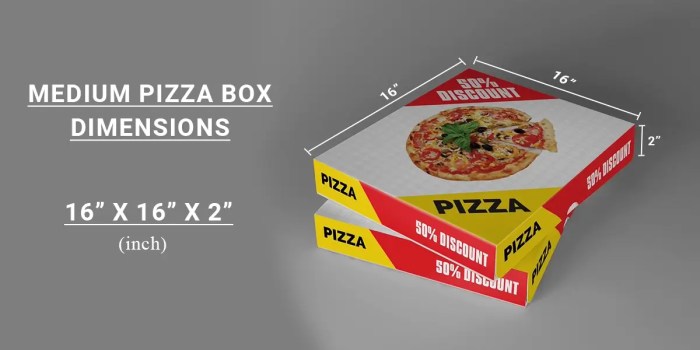

A standard large pizza box typically measures around 16 inches by 16 inches, with a height of 2 inches. For optimal tire performance, consider the Sure Drive Touring Tires, reviewed extensively in sure drive touring tires review. These tires will provide superior handling and grip, so you can enjoy your pizza delivery without worrying about a bumpy ride.

Knowing these dimensions will help you fit your pizza box neatly into your car’s trunk.

This section delves into the practical implications of these dimensions, exploring their influence on the packing process, customer experience, environmental impact, and delivery logistics.

Impact on Packing Process

Pizza boxes, particularly large ones, need to be designed with stacking efficiency in mind. Improperly designed boxes can lead to wasted space in storage and delivery vehicles. The width, depth, and height of the box directly affect how many boxes can be stacked securely without compromising the structural integrity of the boxes themselves. A well-designed box will optimize space and prevent damage during transit.

Stacking boxes should be a consideration during the initial design phase to ensure the pizza box is functional in both storage and delivery.

Impact on Customer Experience

The dimensions of the pizza box directly influence the customer’s experience. A well-designed box, with appropriate size and structural integrity, allows for easy carrying and safe handling. Boxes that are too small can make it difficult to hold the pizza safely, leading to spillage or breakage. Conversely, excessively large boxes might feel cumbersome or unnecessary. Optimizing the dimensions for a satisfying customer experience is essential for brand reputation.

An appropriate size ensures the pizza arrives in perfect condition and maintains its temperature during transport, maximizing customer satisfaction.

Environmental Sustainability

Box dimensions affect the material usage in the production process. Larger boxes, if not designed efficiently, can require more cardboard than necessary. This directly impacts the environmental footprint. A well-designed box, with the appropriate dimensions for the pizza, will use less material without compromising strength or safety. Efficient box designs can minimize waste in the packing and delivery process, ultimately contributing to a more sustainable operation.

Planning your next pizza party? Knowing the dimensions of a large pizza box is crucial for efficient storage and transport. But did you know that finding the perfect home, like those available in houses for sale in peters township , also requires careful measurement? A standard large pizza box typically measures around 16 inches long by 12 inches wide and 3 inches deep, ensuring your slices arrive in perfect condition.

Optimized dimensions minimize material usage, reducing waste and contributing to environmental sustainability.

Implications for Transportation and Delivery

The dimensions of the pizza box significantly influence the transportation and delivery process. Larger pizza boxes can be more challenging to stack and transport, leading to potential damage during transit. Furthermore, boxes that are too large or oddly shaped might not fit optimally into delivery vehicles, resulting in wasted space and potentially impacting delivery time. A proper understanding of delivery vehicle dimensions is crucial for optimizing box size.

Box dimensions need to accommodate efficient loading and unloading while ensuring the pizza arrives in pristine condition.

Stacking Optimization System

A well-structured stacking system in delivery vehicles is crucial for maximizing space utilization and preventing damage to the pizzas and boxes. A systematic approach involves strategically placing boxes, considering their dimensions and weight distribution.

| Box Dimension | Stacking Strategy |

|---|---|

| Width | Boxes should be aligned with the vehicle’s width to maximize space utilization |

| Depth | Boxes should be placed side-by-side to maximize depth utilization, and weight distribution should be considered. |

| Height | Stacking height should be limited to prevent damage and maintain stability. Consider using dividers or padding to prevent shifting. |

This structured approach helps to prevent damage during transport, optimize space, and maintain a safe and efficient delivery process.

Illustrative Examples and Comparisons

Understanding the dimensions of pizza boxes is crucial for ensuring proper packaging and safe transport. Different brands and sizes of pizza boxes employ varying dimensions, impacting the overall experience of receiving a pizza. These variations are directly related to factors like the pizza’s size, the desired level of protection during transit, and the overall design aesthetics of the packaging.Comparative analysis of different pizza box dimensions reveals a wide spectrum of sizes, showcasing the adaptability of packaging to accommodate various pizza sizes.

This exploration helps us understand the practical implications of dimensional choices, ranging from ease of handling to the visual appeal of the final product.

Examples of Large Pizza Box Dimensions

Various brands employ different dimensions for their large pizza boxes. Domino’s, for instance, often uses boxes with specific length, width, and height measurements optimized for their particular pizza sizes and delivery processes. A large Domino’s pizza box might have dimensions of 16 inches in length, 12 inches in width, and 3 inches in height. Papa John’s, another prominent brand, might have slightly different dimensions for their large pizza boxes, potentially reflecting their own production and shipping processes.

These differences in dimensions can impact the overall customer experience, from the feel of the box to the ease of access to the pizza.

Visual Representation of Dimensional Impact

Visualizing how different dimensions affect pizza packaging and transport provides a practical understanding. A box with a shallow depth might struggle to secure a large, thick-crust pizza during transport. Conversely, a box with a deep height might be cumbersome and less user-friendly. Properly designed dimensions, such as those seen in high-quality pizza boxes, balance protection and ease of use.

This balance is essential for a satisfying customer experience.

Comparison Table of Pizza Box Dimensions

| Pizza Size | Length (in) | Width (in) | Height (in) |

|---|---|---|---|

| Small | 10 | 10 | 2 |

| Medium | 12 | 12 | 3 |

| Large | 14 | 14 | 4 |

| Extra Large | 16 | 16 | 4 |

This table provides a basic comparison of pizza box dimensions across different sizes. Note that these are illustrative examples and actual dimensions may vary slightly based on the specific brand and model of the pizza box. This table helps visualize the proportional relationship between pizza size and box size.

Design Features Influencing Dimensions

Several design features influence the dimensional characteristics of large pizza boxes. The material used for the box, whether cardboard or a specialized composite material, significantly impacts the box’s structural integrity and weight. The thickness of the cardboard influences the box’s ability to withstand pressure during transport. Also, the style of the box’s construction, such as the use of reinforced flaps or extra layers of cardboard, plays a critical role in maintaining the pizza’s structural integrity during transit.

Furthermore, the type of pizza (e.g., thin crust, thick crust, deep dish) dictates the necessary dimensions to effectively package and protect it.

Technical Specifications and Standards

Large pizza boxes undergo rigorous design and manufacturing processes to ensure both functionality and safety. These specifications, often dictated by industry standards and safety regulations, are crucial for maintaining consistent product quality and consumer satisfaction. Adherence to these specifications is essential for minimizing risks associated with the use and handling of the boxes.Understanding these specifications provides a detailed insight into the engineering and manufacturing standards behind large pizza boxes.

This enables a deeper appreciation for the complexities involved in producing a reliable and safe product.

Material Properties

Material selection for pizza boxes significantly impacts their durability, strength, and environmental impact. Common materials include corrugated cardboard, which is a composite of various layers of paperboard. Different grades of corrugated cardboard offer varying levels of strength and rigidity. This selection is influenced by factors like the expected weight of the pizza and the handling conditions. The quality and thickness of the paperboard layers are key to maintaining the structural integrity of the box.

Specialized coatings or treatments might be applied to improve moisture resistance, reduce grease absorption, or enhance the box’s overall durability.

Tolerances and Dimensions

Precise dimensions are critical for large pizza boxes. Variations in dimensions can impact the box’s ability to securely hold the pizza and prevent it from shifting during transportation or storage. Tolerances, representing permissible deviations from the specified dimensions, are carefully defined to ensure consistency and maintain the box’s functionality. These tolerances are often expressed as plus or minus a certain measurement from the nominal dimension.

This ensures the box is not too large or too small to fit the intended pizza and maintain structural integrity. The tolerance ranges are set according to the manufacturing process capabilities and the expected use conditions. Overly loose tolerances can lead to poorly fitting pizzas and potential damage during transport. Too tight tolerances can hinder the manufacturing process and increase production costs.

Safety Requirements

Safety is a paramount consideration in the design and manufacture of pizza boxes. This involves complying with various standards and regulations that ensure the box’s structural integrity and prevent hazards during use. Components like the interlocking flaps and score lines are carefully engineered to maintain stability and prevent breakage during handling. The presence of sharp edges or protruding elements is minimized or mitigated to avoid injuries.

Additionally, materials used in the production process must meet safety standards, avoiding any potentially harmful substances.

Industry Standards and Regulations

Industry standards for pizza boxes are developed and maintained by organizations like the American National Standards Institute (ANSI). These standards dictate specific criteria for the material properties, dimensional tolerances, and safety aspects of the boxes. These standards ensure consistent quality and functionality across different manufacturers, enabling consumers to rely on the box’s performance.

Suitability for Intended Use

Determining the suitability of a large pizza box involves evaluating its structural capacity and resistance to the forces it will encounter. The weight and dimensions of the pizza, along with the anticipated handling procedures, are crucial factors. Measurements such as the box’s flexural strength, impact resistance, and ability to withstand compressive forces are considered. These tests are conducted to ensure the box can safely hold the pizza and withstand the rigors of transit.

Manufacturing Processes

The manufacturing process for large pizza boxes typically involves several steps. These include the preparation of the paperboard sheets, the corrugation process, the gluing and assembly of the box components, and quality control checks. Each step is designed to ensure that the box meets the specified tolerances and material requirements. Sophisticated machinery is often employed to achieve the required level of precision and efficiency in manufacturing.

Quality and Durability Factors

The quality and durability of large pizza boxes depend on various factors, including the quality of the raw materials, the precision of the manufacturing processes, and the environmental conditions during storage and use. Maintaining consistent moisture levels and proper storage conditions for the cardboard is essential to prevent warping or damage. The quality of the adhesives used in the assembly process plays a critical role in the long-term durability of the box.

Proper handling procedures and packaging techniques further enhance the longevity and integrity of the box.

Final Conclusion

In conclusion, the dimensions of a large pizza box are a complex interplay of factors, from the size of the pizza itself to the demands of efficient packaging and delivery. Understanding these dimensions is critical for businesses and consumers alike, affecting everything from the cost-effectiveness of packaging to the environmental footprint of pizza delivery. The specific dimensions are key to optimal packing, transport, and customer experience.

FAQ Guide

What are the standard units of measurement used for pizza box dimensions?

Inches (in) are the most common units used for measuring pizza box dimensions.

How do different pizza sizes affect box dimensions?

Larger pizzas typically require larger boxes with increased length, width, and height to accommodate the pizza and ensure it arrives in good condition.

What materials are commonly used for large pizza boxes?

Corrugated cardboard is the most common material due to its strength, affordability, and recyclability. Other materials, like paperboard or plastic, may also be used.

What are the implications of pizza box dimensions for environmental sustainability?

Optimizing dimensions can minimize material usage, leading to reduced waste and a more sustainable packaging solution.